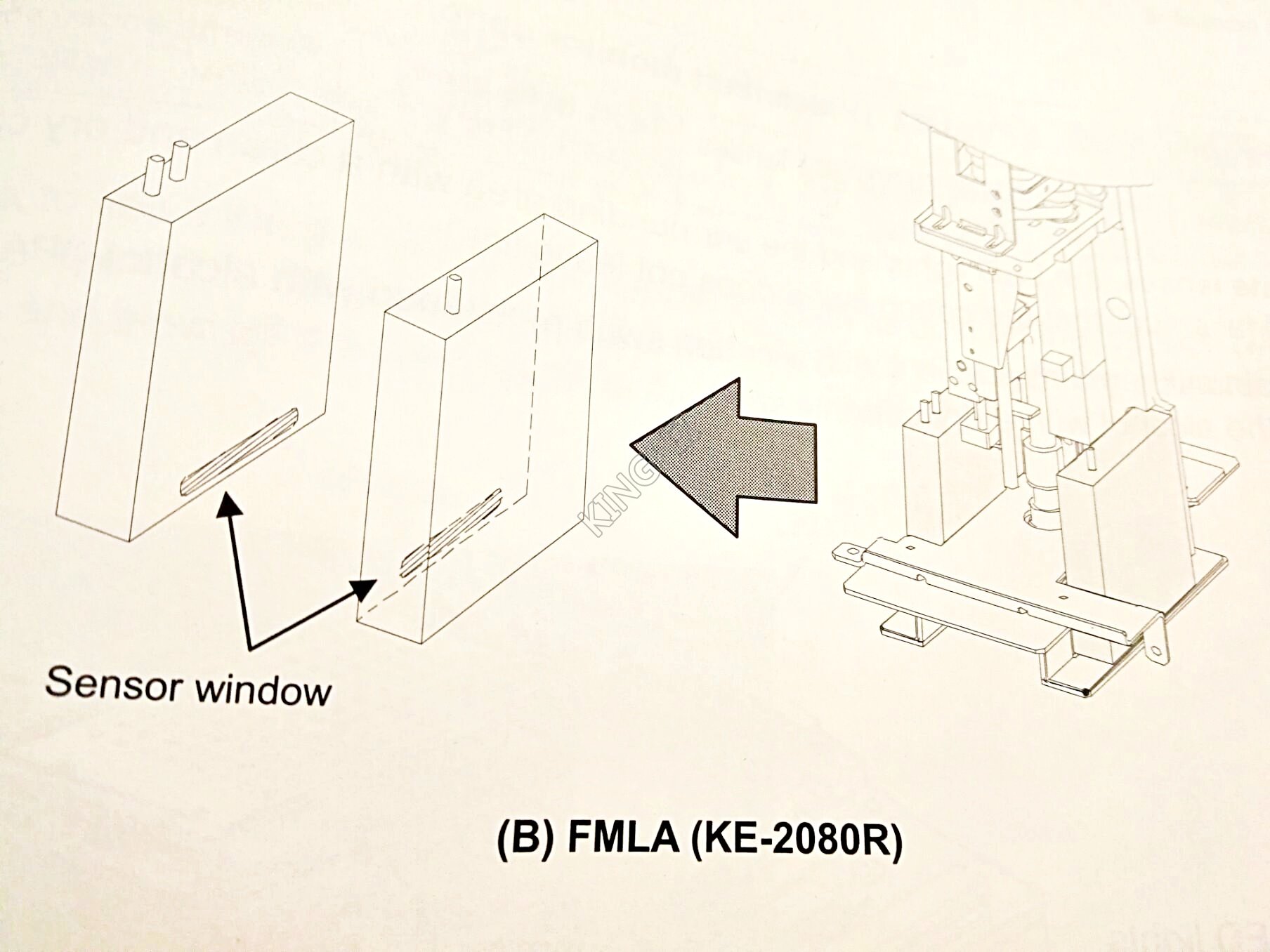

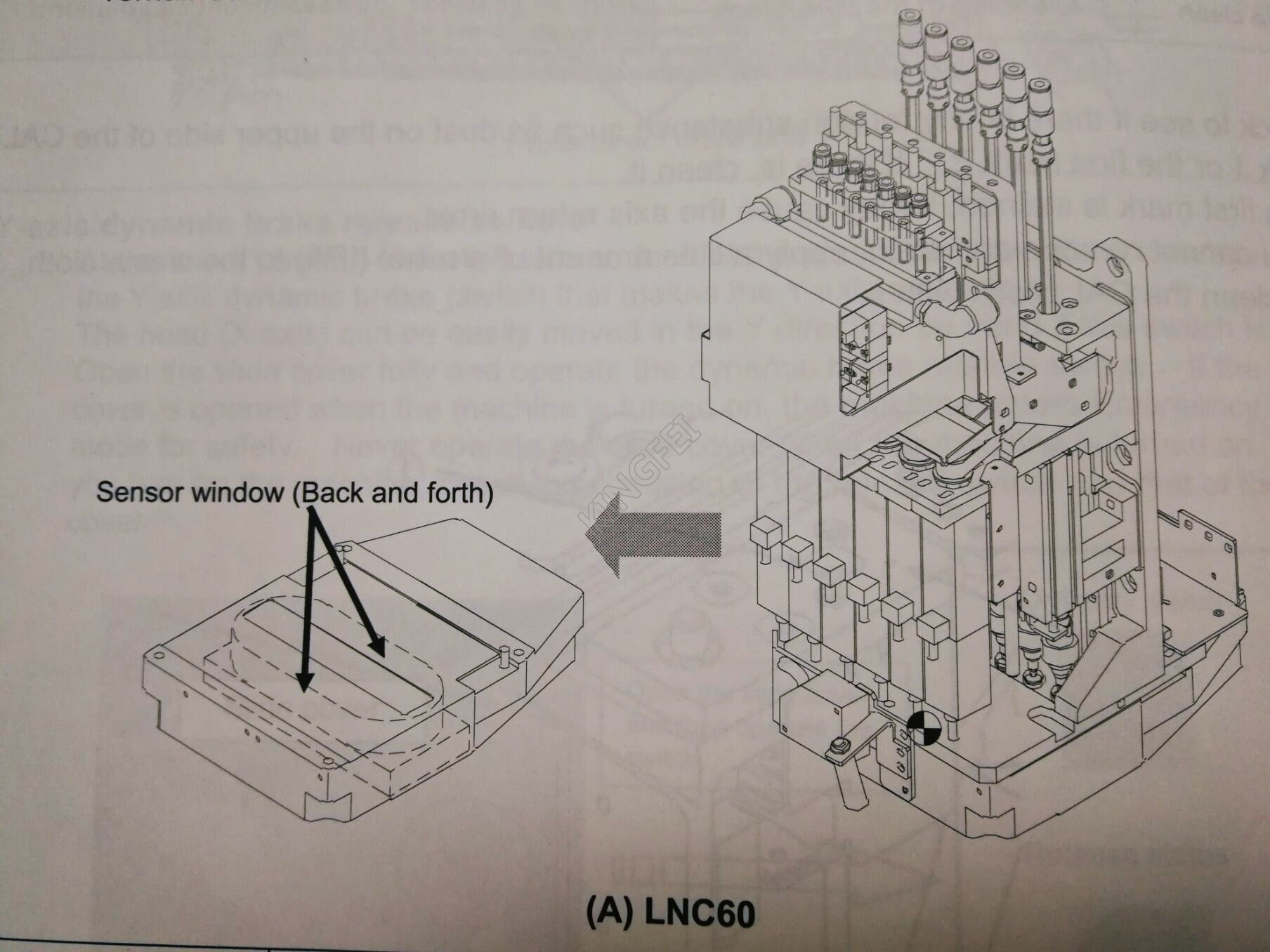

How to clean the laser align sensor LNC60/FMLA?

Dec 26, 2021 Editor: admin

Cleaning of the laser window by waste cloth and cotton swab:1, When a " stained laser head error" occurs during PWB production or on a regular basis, every week check to see if the laser head is stained. If the laser head is stained, clean it.

2, We recommend that you clean the sensor window every week. However, if it can be stained easily, you have to clean it at the shorter intervals.

How to check?

First, set the <User Level> to <Manager> or Higher.

Then, select the <Manual control> command, the <laser control> command, and the <Edge check disp> button in this order to check to see if the laser head is not stained.

How to Clean?

i Clean the window (four positions on the front and the rear) with waste cloth with no fluff or contton swab moistened with alcohol once in one direction only.( Note: if you wipe the window back and forth, dust may remain on the window or it may damage the window)

ii Wipe the window with dry waste cloth only in one direction to remove alcohol remained on the window.

Caution: if you use not alcohol but any solution such as acetone and thinner, the resin part around the sensor window may fuse. Never use any solvent other than alcohol. Moreover, never apply the air blow to the sensor window because the foreign substances such as dust entered into the sensor might influence the operation in recognition.