-

How to register customized nozzle data into mounter?

Registered nzl. no table This command displays the list of the nozzles already registered and their information on the screen. When you select the Registered nzl. no table command from the filemenu, the Registered nozzle no. table dialog box appears o [Read More] Jan 01, 2022

-

How to do maintenance of the nozzle?

Cleaning of the nozzle(Tool to be used: Ultrasonic cleaner) 1, Dampen the entire nozzle whose number is from 500 to 504, 509 in alcohol, and clean it with an ultrasonic cleaner or similar tool for five minutes. 2, To prevent the urethane section of th [Read More] Dec 28, 2021

-

Inspecting Vacuum Filter for dirt

Checking the filter for dirt 1) Check the vacuum pressure by the negative pressure gauge provided at the front of the equipment when the vacuum pump is in operation. * Check it when a vacuum operation is not in progress. 2) If the value indicated with [Read More] Dec 28, 2021

-

Maintenance of transport screw shaft(shaft)

Transport screw shaft(shaft): 1 Screw shaft on each side, right and left. Apply grease to the entire surface of screw shaft. Tool to be used: Brush Grease to be used: 6459 Grease N Transport guide shaft: 2 Guide shaft: 2 on the left, 3 on the right. A [Read More] Dec 28, 2021

-

How to lubrication nozzles?

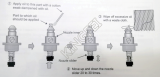

Applying of oil to a nozzle after cleaning it by air gun, cotton swab and waste cloth. If you leave the nozzle without doing anything to it after cleaning it, the inside of the nozzle may be rusted. Follow the procedure below to apply oil to the nozzl [Read More] Dec 28, 2021

-

Maintenance of the nozzle outer

Clearing of the nozzle outer by cotton swab and waste cloth every month 1, Clean the inside of the nozzle outer with a cotton swab dampened with alcohol 2, Clean the surface and the spring section of the nozzle outer with alcohol Lubrication: Applying [Read More] Dec 27, 2021

-

Ball Screws and spline shaft head part

Every two months using brush to do lubrication the ball screws and spline shaft by CG2 grease. Apply a light coating of grease(CG2 grease) to the ball screws rails. Apply a light coating of grease(CG2 grease) to the spline shaft axis. After fitting grease [Read More] Dec 26, 2021

-

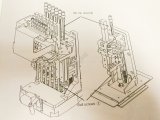

overall feeder exchange trolley

Cleaning of dust and/or a foreign substance from the feeder bank [Read More] Dec 26, 2021

-

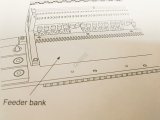

Cleaning the feeder bank

Cleaning of dust and/or a foreign substance from the feeder bank Clean the feeder bank on regular basis. In addition, clean the feeder bank with a cleaner or similar device if there is a foreign substance such as a chip on it before attaching a feeder suc [Read More] Dec 26, 2021

-

Cleaning of dust and/or a foreign substance from the ATC by waste cloth

If there is a chip or a foreign substance on the slide plate, it may cause a nozzle detachment/attachment failure. Clean the slide plate with waste cloth or similar cloth dampened with alcohol. [Read More] Dec 26, 2021